The ever increasing demand for reductions in the unit cost per work piece ground, drives the quest for abrasive wheel manufactures like Phoenix to continuously strive for technology advantage.

The ever increasing demand for reductions in the unit cost per work piece ground, drives the quest for abrasive wheel manufactures like Phoenix to continuously strive for technology advantage. Recent developments in our new organic bond technology has produced new bond systems allowing for the inclusion of “SolGel” ceramic abrasive grits, which provide a unique combination of hardness and toughness with high stock removal and per forms equally well grinding ferrous or nonferrous metals. The benefits delivered from this new generation of wheel, which give 30-50 percent longer life, far out weigh the higher cost of the wheel.

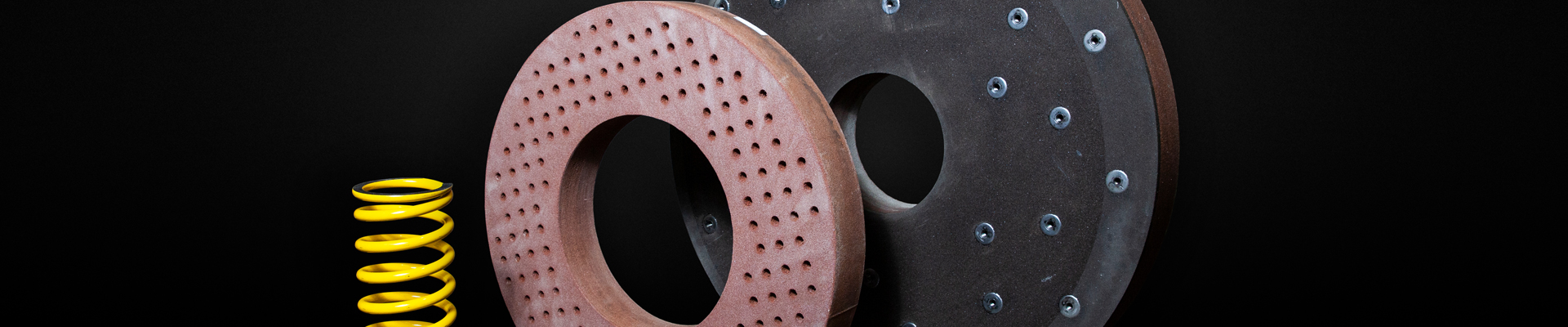

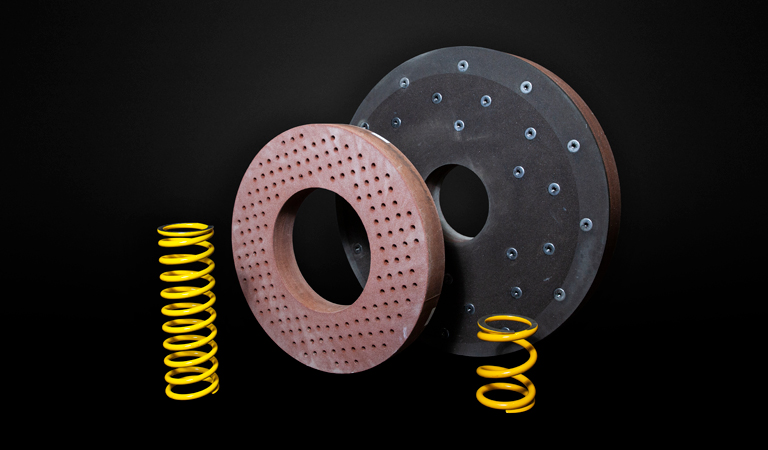

Grinding machines; Bennett's, Diskus and Giustina take wheels within the diameter range 200mm to 915mm with various nut patterns for grinding: Springs, Cylinder heads, Piston Rings, Valves, Bearing races, Bearing roller end, Pliers, spanners and sockets.

Vertical or horizontal spindle machines fitted with resin bonded abrasives segments are the optimum method of achieving a heavy, fast and economical way of stock removal.

Segments are available in a variety of shapes and sizes to suit the design of the machine.

The number of segments per set is dependant on the overall diameter of the segmental arrangement and the capacity of the machine.

Segments are fitted in the grinding head or chuck and held in place by ‘wedges’.

With high powered vertical spindle machines capable of delivering heavy grinding pressures it is critical that compliance with the safety rules as per ISO EN 12413:1999 are met.

The maximum unsupported length of segment protruding from the chuck must not be greater than 1.5 times the thickness of the segment.

To gain cost benefits the segmental grinder should be fitted with the maximum length segment the machine can accommodate without contravening the above safety rule. Softer ‘grades’ are the norm in segmental grinding owing to the greater contact area of segment on work piece.

The choice of ‘grit’ size to be used is dependant on the material to be ground and the finish required.

The introduction of machines using 250hp motors with improved feed rates can deliver stock removal rates of 250kg per hour. This is very cost effective when compared to the modern planning and milling methods.

Resin bond segments reduce grinding costs by the ability of the segment to:

Grind difficult materials or a combination of materials. Heavy stock removal without jeopardising the requirement surface finish.

Provides a complete Abrasive Machining Process.

Scroll left and right to see more

| MACHINE | SHAPE | TOP(mm) | BASE(mm) | THICK(mm) | LENGTH(mm) |

|---|---|---|---|---|---|

| LUND 4183 | SS/12 | 84 | 103 | 38 | 152 |

| CHURCHILL | SS/16 | 84 | 103 | 38 | 229 |

| CHURCHILL | SS/17 | 100 | 81 | 38 | 190 |

| CHURCHILL | SS/18 | 84 | 103 | 38 | 190 |

| CHURCHILL | SS/25 | 84 | 103 | 38 | 203 |

| LUMSDEN | SS/13 | 117 | 79 | 44 | 152 |

| LUMSDEN | SS/14 | 117 | 79 | 44 | 203 |

| LUMSDEN | SS/21 | 117 | 79 | 44 | 190 |

| LUMSDEN | SS/22 | 117 | 79 | 44 | 229 |

| SNOW H1(V18) | SS/19 | 89 | 117 | 44 | 203 |

| SNOW H2(V12) | SS/6 | 89/117 | 95 | 44 | 152 |

| SNOW H2 (V12) | SS/26 | 89/117 | 95 | 44 | 203 |

| SNOW H2 (V12) | SS/27 | 89/117 | 95 | 44 | 254 |

| SNOW H2 (V12 | SS/28 | 89/117 | 95 | 44 | 180 |

| SNOW No.4 (GA32) | SS/8 | 110 | 95 | 44 | 254 |

| SNOW No.4b | SS/1 | 106 | 85 | 44 | 254 |

| SNOW B2 (G26) | SS/5 | 222 | 154 | 76 | 305 |

| SNOW 1A | SS/7 | 222 | 158 | 100 | 406 |

| SNOW B1 | SS/10 | 222 | 131 | 95 | 305 |

| SNOW B2 (G20) | SS/20 | 222 | 154 | 76 | 305 |

| LUMSDEN | SS/23 | 168 | 114 | 57 | 229 |

| LUMSDEN | SS/24 | 168 | 114 | 57 | 305 |

| SNOW IC (GA14) | SS/2 | 152 | 84 | 76 | 229 |

| SNOW C1/7 | SS/9 | 152 | 84 | 76 | 178 |

| SNOW GB42 | SS/11 | 270 | 216 | 100 | 305 |

| SNOW 2C | SS/3 | 152 | 108 | 44 | 203 |

| GOCKLE | SS/30 | 63 | 80 | 32 | 127 |